Onshore and offshore cables connect land and sea

Our on- and offshore cables are optimally designed to overcome the particular challenges of data and energy transmission at sea and on land. They connect wind turbines, converter platforms and other plants safely and efficiently via grid infrastructures, both in harsh marine environments and in stable onshore applications.

Reliable and resilient on- and offshore cables

Reliable power supply for wind farms and other on-/offshore systems with quality that stands the test of time.

Optimised data transfer for wind farms, converter platforms and other systems. Fast, safe and reliable.

All product certifications at a glance

All of our cables and wires meet the highest quality standards and are ideal for maritime and industrial applications. Take a look at all product certificates here and download any PDFs you may need.

Overcoming special challenges with offshore cables

Offshore cables form the essential link that routes energy and data flows through the depths of the ocean by reliably connecting wind turbines, converter platforms and other offshore structures to the mainland. The offshore cables face unique challenges: the harsh conditions of the seabed, the constant effects of salt water and the immense depth of the sea require special designs and materials. Our cables are designed to meet these challenges by ensuring a reliable, continuous connection for electricity and data between on- and offshore facilities. Discover how our offshore cable installation bridges the gap between advanced technology and the challenging conditions of maritime environments by ensuring a reliable connection for the secure and efficient transmission of power and data across the vast sea.

Plan your project requirements with us

Get personal advice from our experienced team of experts today and benefit from our many years of expertise in the national and international market environment. We fully understand industry and product requirements in the maritime and industrial sectors.

Our advantages for you

From advice to assembly and worldwide delivery: in addition to high-quality on- and offshore cables, we also offer comprehensive services. Our experienced team will be happy to advise you when selecting the right cables and can offer custom solutions for your individual requirements. You also benefit from fast delivery times and flexible order processing.

Frequently asked questions about on- and offshore cables

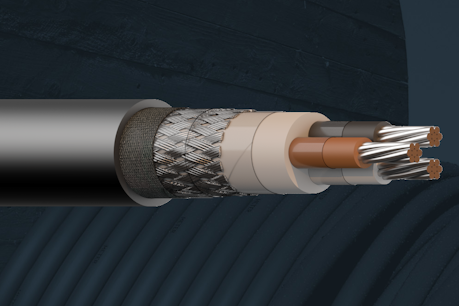

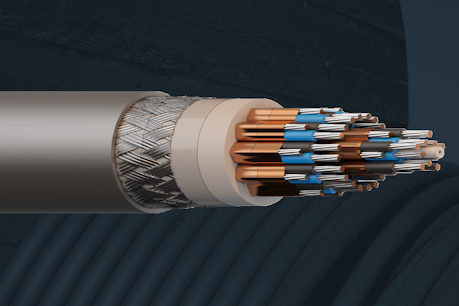

On- and offshore cables are used to connect wind turbines and converter platforms on land or at sea to the energy grid. The submarine cables are used for energy and data transmission and are laid on the seabed. Offshore cables are individually calculated for each application, with the internal cable core protected from mechanical damage by a steel braid.

The differences between onshore and offshore cables relate to their material properties and how they are laid. These special cables connect wind turbines to each other and with the converter station. As submarine cables, offshore cables in particular need to meet high requirements, e.g. in terms of resistance to the sea water as well as to mechanical damage, for example from ship anchors. There are also differences in the laying technology: special laying vessels are used for offshore cable laying, which lay the cables in the seabed using ploughs or jet sleds. Onshore cables are underground cables laid in special pre-installed cable ducts. Due to the heavy weight of the cables, powerful means of transport, tools and machines are required.

Offshore submarine cables are laid in the seabed and are exposed to extreme conditions there, including high pressure, low temperatures and constant motion. Salt water and marine animals, as well as mechanical factors, also affect the cables on a continuous basis. To ensure the robustness of the submarine cables, sophisticated technological solutions are required both for the material itself and the offshore cable-laying. The special cables are encased in several layers of sheathing with resistant materials and protected from mechanical damage by a galvanised steel mesh. The cables are laid in the seabed using special ships with a high load capacity and special equipment such as ploughs and jet sleds.

On- and offshore cables must meet high national and international standards such as IEC and ISO standards. National standards also play a key role, for example, in the cross-border laying of offshore cables and must be taken into account on a customer- and application-specific basis in the planning and assembly process.

Without suitable cables, the operation of wind farms as part of the energy transformation and effort to reduce carbon emissions would simply not be possible. With their special characteristics, on- and offshore cables enable connection to the grid on land and at sea and transmit energy and data. These special cables have tailored protection in order to durably withstand the stresses, particularly offshore. This is essential to ensuring grid stability and securing the supply of energy from wind farms as a renewable energy source at all times.

To secure the energy supply and reliable grid stability, offshore cables are closely monitored with sensor technology. If faults and damage occur, underwater robots and special repair ships are on standby to rectify them quickly and effectively. To maintain an uninterrupted flow of electricity and information, a strategy of preventive inspection and maintenance ensures that even the smallest damage can be rectified preventively.

For on- and offshore use, Friesland-Kabel offers power and control cables such as BFOU, RFOU, LKM-FRSHF2, LKM-SHF2, LKMSM-SHF2 and LKSM-EMC-SHF2, control and instrumentation cables such as LKSM-SHF2, as well as instrumentation and communication cables such as BFOU (i), RFOU (i), RFE-FRSHF2, RFE-SHF2 and RFE-SHF2. All cable types meet the highest standards in terms of material quality and processing and comply with norms, standards and regulations such as NEK 606. Our experts are happy to assist you with your projects and requirements.

Every offshore cable-laying scenario has its own specific requirements. To ensure ideal grid connection and standard-compliant laying and use of cables, we offer customised solutions and individual cable assemblies for offshore cables. We cut, tape and label the cables according to individual customer requirements and are happy to provide further services as well. We offer our customers both time to time and just in time delivery.